| Problem | If | Possible cause | Because | Solutions | Resources |

| Probing the piece length fails with error on screen "g38.4 or G38.5 move finished without making contact" or "probe is already tripped when starting G38.2 or G38.3" | error is intermittent | ultrasonic probe sensor is wet or dirty | Water and dirt are affecting sensor range | blow air on sensor and wipe with a clean rag | |

| bad sensor cable | cable worn out making false contact | replace sensor cable 15.11 | EPR schematics | ||

| error is permanent | Sensor needs range calibration | Change in ambient humidity and ambient noise can affect range calibration | Reset ultrasonic probe sensor range | Reset ultrasonic probe sensor range | |

| Sensor moved inside casing | strong vibrations, not well tight sensor | Adjust sensor inside white plastic tube protection casing, tight the nut properly, do not overtighten to avoid sensor damage | |||

| bad sensor cable or bad sensor | sensor was hit, water damage inside sensor plug, cable cut or damaged | Replace ultrasonic sensor and or sensor cable 15.11, check for proper 24V DC from 15.11 to L+ to identify problem | EPR schematics | ||

| sensor makes light | Sensor needs range calibration | sensor lights don't change when a piece is slid under the sensor. | Reset ultrasonic probe sensor range | Reset ultrasonic probe sensor range | |

| Sensor input is not read, bad cable or sensor | sensor lights changes when a piece is slid under the sensor. | Replace cable 15.11, check for proper 24V DC from 15.11 to L+ to identify problem | EPR schematics | ||

| sensor makes no light | Damaged sensor | there is proper 24V DC on sensor cable | replace ultrasonic sensor | ||

| Damaged cable | there is NOT 24V DC on sensor cable | replace ultrasonic sensor cable | |||

| sensor light flashes | Sensor body has voltage | machine frame has residual currents | isolate sensor body from machine frame with isolation tape | ||

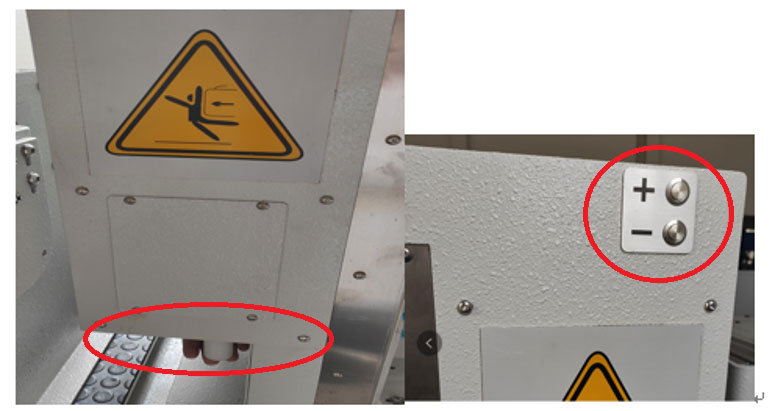

| false contact from "+" and "-" buttons | "+" and "-" buttons are wet or stuck | press buttons to get unstuck, check continuity, cut cables if necessary, look at page 15 of schematics | EPR schematics |

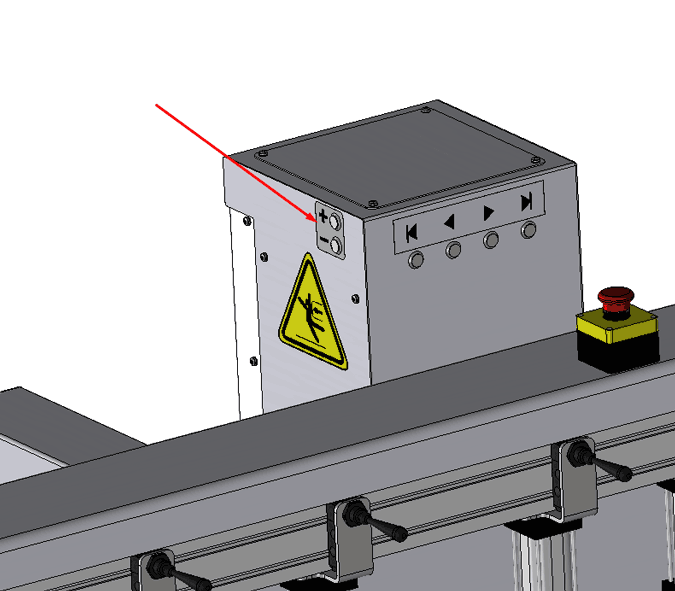

¶ Reset ultrasonic probe sensor range

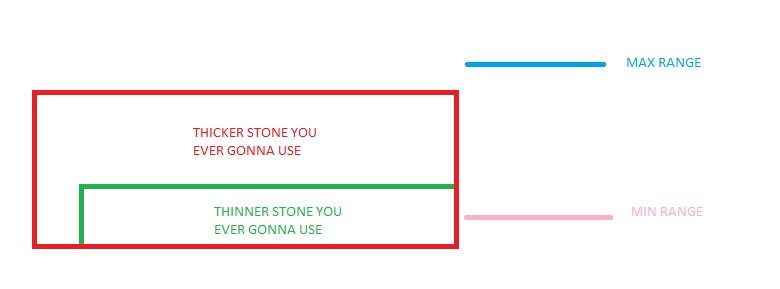

Place a thin piece of wood or cardboard on the table and then hold the + button for 5 sec this will set the lower limit of the range, then you hold the cardboard at 1/2 inch (10mm) from the white tube and you hold - button for 5 sec, that should set the range, if it doesn't work, try to do opposite when you set low hold + and when you set high hold - . It is possible to open the side cover to observe the sensor light flashing to acquire new range, and also to check that it can read a stone when put under the sensor.