¶ Intro

VNC viewer or TigerVNC are used on AitalMAC machines with CNC controller and Windows computer, either one will be installed on the Windows computer and either can be used to display and remotely control the CNC controller.

An alternative to VNC is directly connecting screen mouse and keyboard to the CNC controller.

If VNC is not installed because of windows computer reset, please download the binary from here

Download and install

Depending on your machine model and manufacturing year you may have TigerVNC or VNC Viewer, you can use either with these instructions.

¶ Connecting

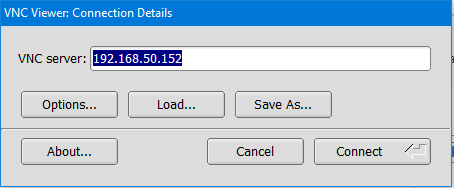

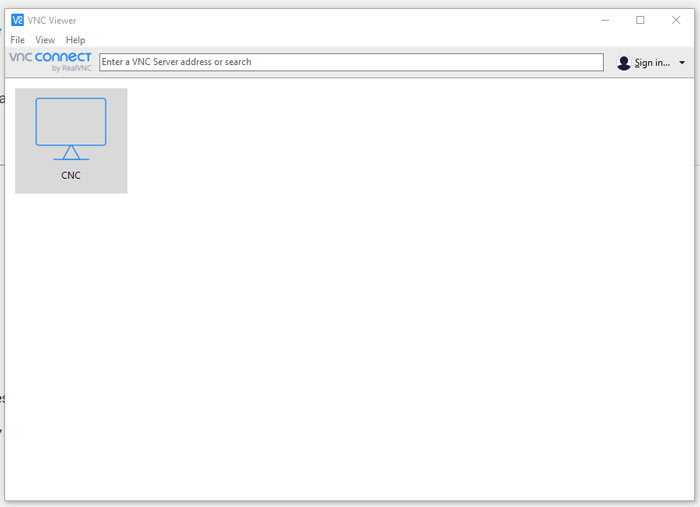

The most common IP for the CNC controller on AitalMAC machines is 192.168.50.152, on VNC Viewer you should already have a configuration with that IP, double click to connect, on TigerVNC make sure IP is proper and press connect

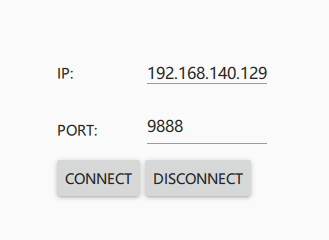

If this address is not reachable, please check address is correct by comparing with the IP address the machine interface is trying to connect to

If also interface IP is not correct, open a command window in windows and Input the command arp -a this command displays all active IP addresses connected to the local network.

Then use ping 192.168.xx.xxx with correct IP address to check for response.

Alternatively connect screen, mouse and keyboard on the CNC controller, open a terminal window and input the command ifconfig to display information about the IP of the controller.

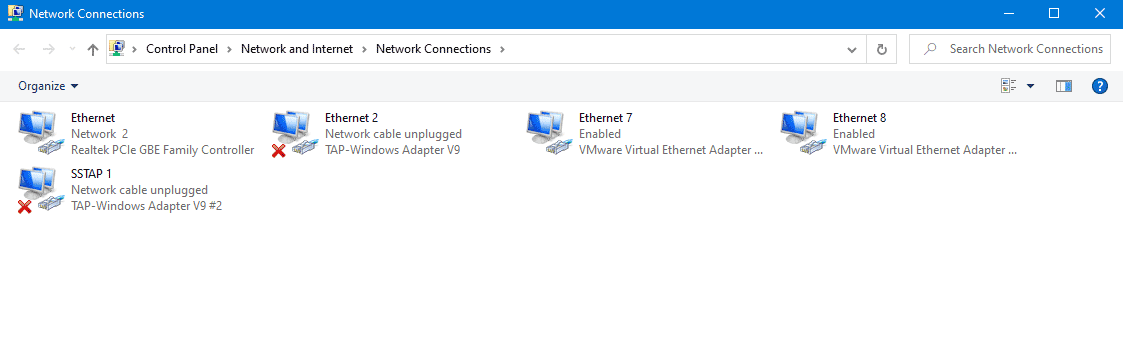

If it's not possible to connect even tough the IP is correct and the computers are networked correctly, check internet cables and check the internet configuration on windows.

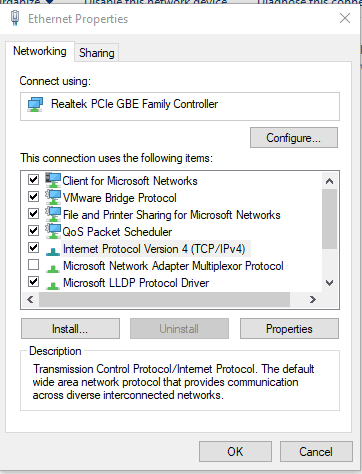

navigate to Control Panel\Network and Internet\Network Connections

right click on the Ethernet connection that connects with the machine (not the WiFi adapter used for internet), and click properties,

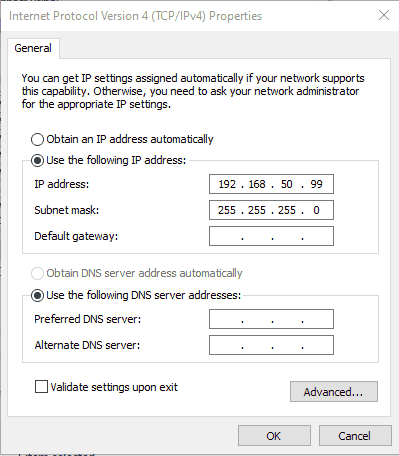

click on Internet protocol Version 4 and click properties button,

Please set using the following IP like in the picture above, do not set a gateway or a DNS since this connection does not require internet.

¶ Useful commands

Ctrl+t open terminal window

linuxcnc open or restart CNC program (models before 2020)

aitekcnc open or restart CNC program (models after 2020)

For these commands to work CNC program must be running

halshow display halshow window where you can check pin values and status look at pin list to understand naming of the pins related to the names in electrical schematics gpio_to_pin.pin save and open with text editor

halscope similar to halshow but can also read noise in the signals

halcmd setp modbus_1.show 1 display axis drivers modbus manager pmodbus

halcmd setp modbus_2.show 1 display spindle modbus manager pmodbus

halcmd setp comp.4.hyst 999999 unlock C axis on orbit A5 to home on any turn

halcmd unlinkp joint.4.neg-lim-sw-in unlinks the limit signal for C axis min limit

halcmd setp joint.4.min-lim-sw-in 0 set minimum limit of C to be off

halcmd unlinkp joint.4.pos-lim-sw-in unlinks the limit signal for C axis max limit

halcmd setp joint.4.pos-lim-sw-in 0 set maximum limit of C to be off

dpkg -l | grep cncserv check cncserv installed version

halcmd setp halio.pos.enable_save allows new home position to be stored for automatic homing (only needed if cncserv is version 88 or more) (does not work on models after 2021, there is new tab for machine parameters where to set this now)