¶ Hydraulic pump intro

The hydraulic pumps on AitalMAC's machines use hydraulic oil ISO 32 or 48, and have a 15~20 Liters tank.

Fill up oil with a clean funnel, avoid any dirt residue to contaminate the oil.

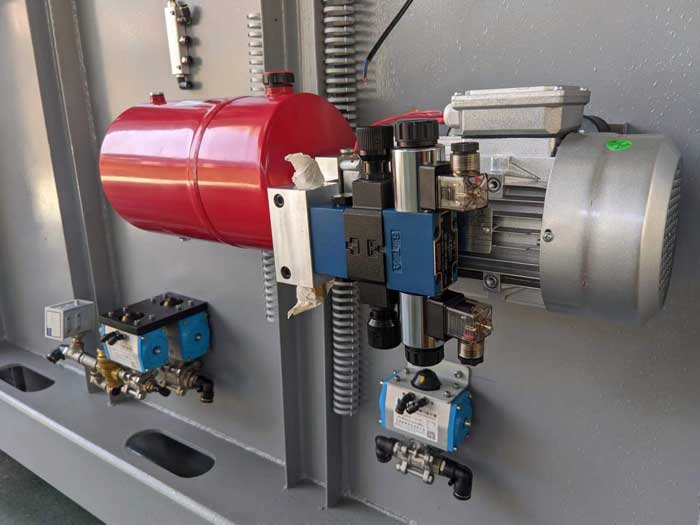

Opening valve block

Prepare a clean surface to work on for working on the valves, and clean towels to keep the area clean.

Lower the table to a close position.

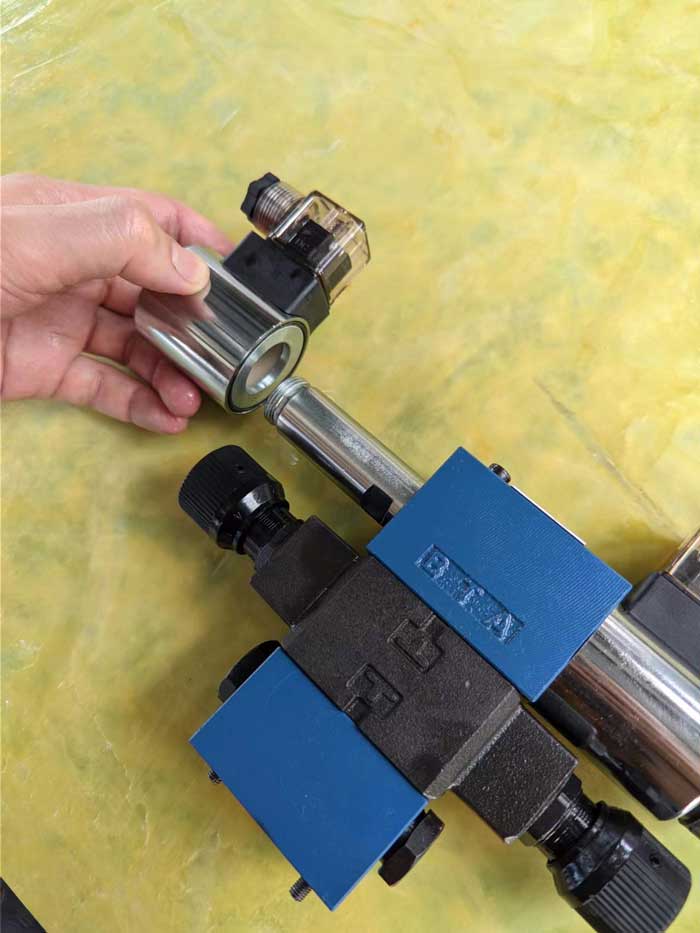

Remove the pipes, and the wire plugged on the solenoids, take a few pictures to make sure you assemble it back the proper way.

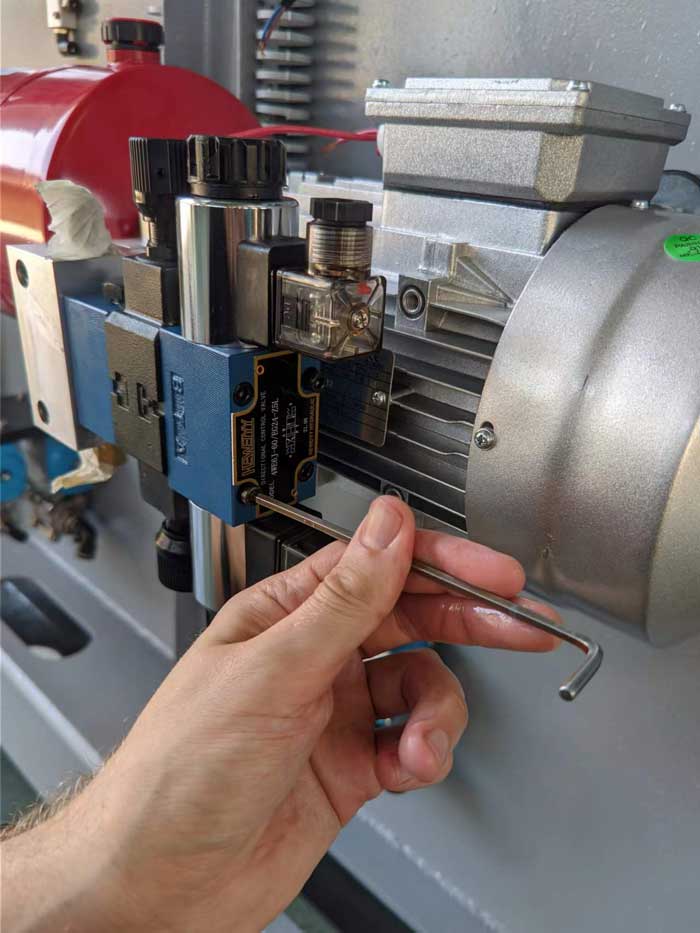

Use allen wrench size 4mm top opening these screw, hold the valve block with your hands as it is only held by these 4 screws and it will fall once they are out.

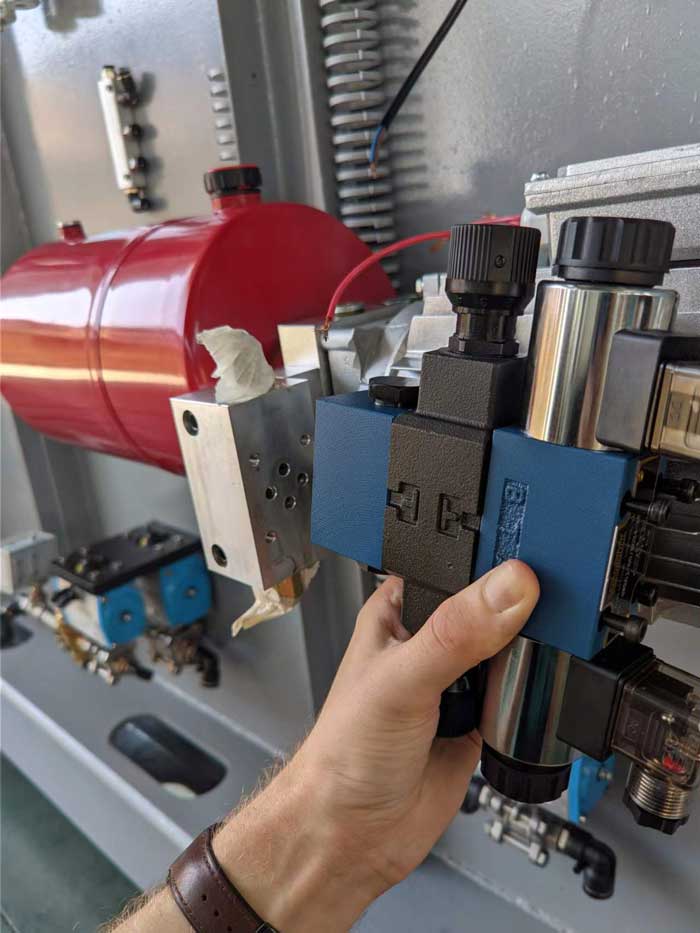

Hold the block, keep towels arond to deal with excess oil, make sure no seals fall on the floor, bring the valve block to a clean surface to work on it.

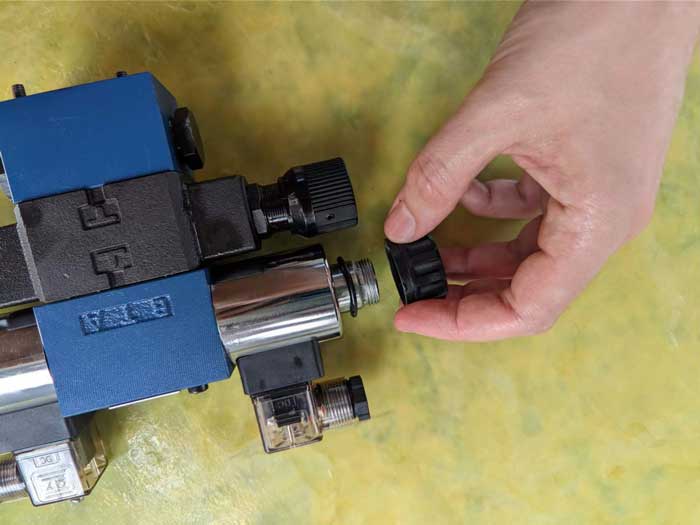

Take pictures of your valve assembly to make sure you put it back properly, then unscrew the plastic knobs that hold the solenoids.

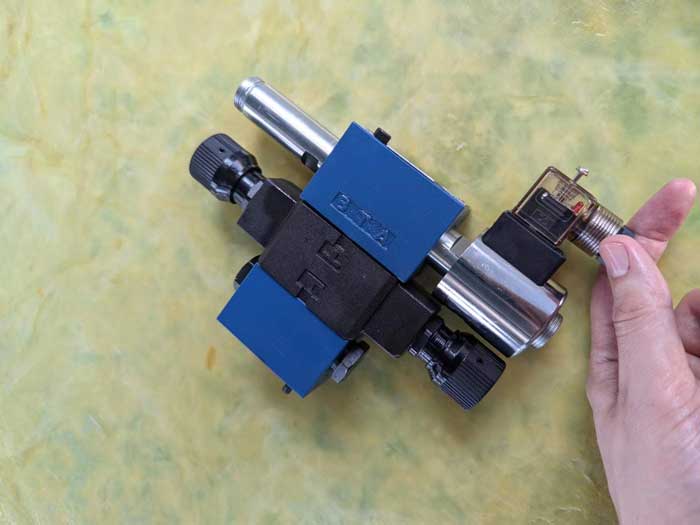

Also pull out the o-ring seal but keep track of it.

Pull out the solenoid, and notice o-ring seal also on the other side of the solenoids.

Notice the O-ring seal on the valve block, make sure they do not drop out, if they do put them back

use one of the screws to push the center of the valve shaft.

take a look inside, the inside should move without much force, and should spring back, use compressed air while moving the insides to try and blow any residue out.

keep the regulator oriented properly, and blow it clean as well

also this final block, this resticts the oil direction, give it a clean with dry compressed air, make sure not to loose any seal, and to keep it very clean, and oriented the same way it was.

mount the valve cblock back, and slide the solenoids back in.

remember the o-ring seal and screw the plastic knob to hold the solenoid, hand tight.

do the same for the opposite solenoid.

make sure the o-ring is there before screwing the knob.

blow clean also the block that stayed on the pump, and assmble the valve block back.

tighten the screws well. and mount the power plugs, and the oil pipes.