¶ New EPR spindle motor details

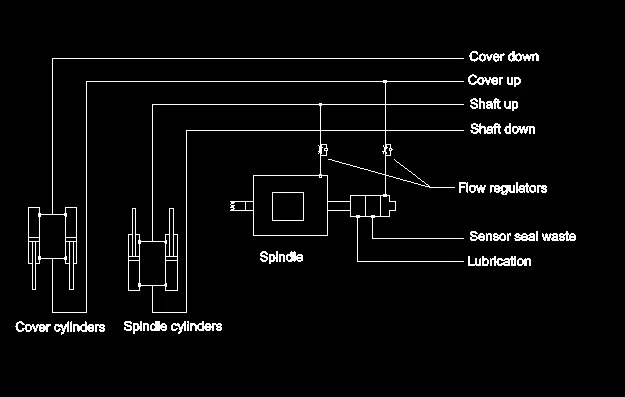

If you received a new spindle motor with different points for pneumatic hook ups, please follow this diagram below for correct hook up

IMPORTANT: if this is first time you hook up a new motor, the software configurations must be updated, please contact AitalMAC service to run the update.

The cover up air manages spindle sealing air for the water trough spindle shaft, this makes sure the water is directed only trough the spindle shaft, and doesn't leak in the motor.

And the shaft up air hooks up directly to the motor casing, to pressurize the spindle motor body, to avoid water getting inside while working with water.

The sensor seal, will send water to a propeller sensor, that will stop the machine in case of unexpected leaks, this sensor also needs to be hooked electrically to the machine, contact AitalMAC service for details.

¶ Pressurize the motor body

Make sure the air comes out the motor front when the shaft is up.

Adjust the flow regulator that's on the spindle cylinders, and goes to the body of the spindle, to adjust the flow.

¶ Water pressure without air

Adjust the flow regulator for the spindle seal to nothing, and check the water pressure, adjust water pressure with the pressure regulator where the water is hooked up to the machine, if you do not have a pressure regulator, please install one.

¶ Seal air flow

Adjust the flow regulator for the spindle seal till you have a result similar to the video below.

¶ Water pressure with air

Have another feel for the water pressure, and adjust to proper amount for polishing.